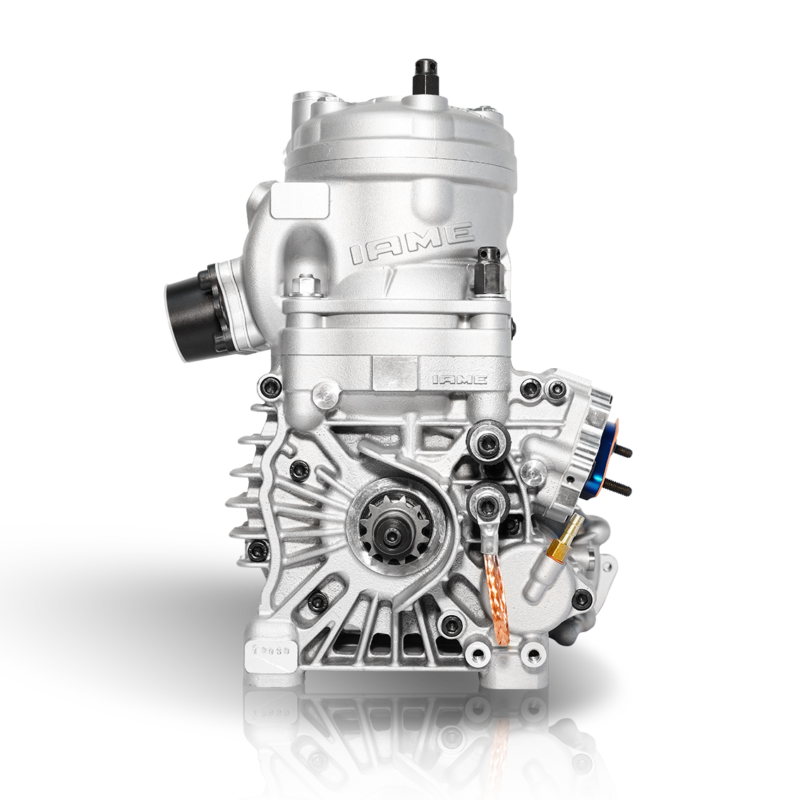

The X30 Codasur is a racing machine designed to meet South American drivers demanding needs and to ensure the most extreme racing experience.

Big Displacement, pure power, no Power Valve

Very high power level and impressive torque diagram

Essential racing design, compact size, light weight

Locked RPM range to increase durability and reliability

Water cooled cylinder, cylinder head and crankcase rear side.

External water pump

Direct drive transmission. True racing experience. Less troubles. Lower costs.

Limited vibrations by integrated balancer shaft

Automatic decompressor on the cylinder head. Easy start. Easier handling of the vehicle off the track

Cost-effective engine design

Reduced maintenance in comparison with the existing Sudam engines

High performance consistency

The new Era of Karting

A new challenge is launched! Offering racers a new concept of power, reliability and low service costs compared to any existing Karting engine.

Starting from the benchmark set by the Sudam 125cc engines range, the most simple and performing two stroke engines for Karting still produced, IAME raises the level of the target with the X30 Codasur, still preserving mechanical simplicity and providing the Sudam a worthy companion and successor.

The development project is drawn around three key featurs:

1- Extremely exciting performance level for the ultimate driving experience

2- Reduced maximum RPM to preserve durability

3- Foreclosure of the Power Valve. Yet a very well system, it can be source of problems and tricky to users in some situations

IAME Engineers have decided to raise the displacement to 175cc.

In order to maintain the crankshaft compact and light, the bore is increased to 64mm with the well tested stroke at 54.4mm.

The result is a sensational race machine!

CYLINDER

Made by gravity casting in high-strength aluminum alloy, the X30 Codasur cylinder is paired with a cast iron liner. This is the core of the engine. Manufactured at IAME by precision 5-axis CNC machines. The tight manufacturing tolerances guarantee the consistency of performance throughout the production.

MAIN BEARINGS

The main bearings are special roller bearings manufactured by SKF in cooperation with IAME. The result ensures a significant increase of the crankshaft alignment accurancy and reduces friction. The inner ring is forced into the crankshaft seats ensuring preservation of the crankshaft journals from wearing and an extremely long life.

IGNITION

The ignition is a simplified digital plant made by PVL specific for Karting applications. The low inertia of the internal rotor reduces solicitations on the crankshaft and helps reducing the engine overall weight. The locked digital programming sets the rev. limitation.

The electronics are built in the coil, different for Senior (15.000rpm) and Junior (14.000rpm).

CYLINDER HEAD

Made by gravity casting for the best stability. The combustion chamber volume has been set to achieve the best compromise between performance and combustion efficiency.

CONROD

The conrod is completely CNC machined from forged steel and provided in classic “knife shape” design. Reasonably long to contain piston’s lateral load and supported by precision roller cages on both ends.

ENGINE INSTALLATION

The engine installation is extremely simple.

A universal engine mount, suitable for the most diffused chassis is available as optional spare part.

DECOMPRESSION VALVE

The automatic decompression valve is installed directly in the cylinder head.

Easier handling of the vehicle off the track

PISTON

The piston is casted with a particular fatigue-resistant alloy. It is a typical two-stroke design with one flat ring. Made of steel and chromium plated.

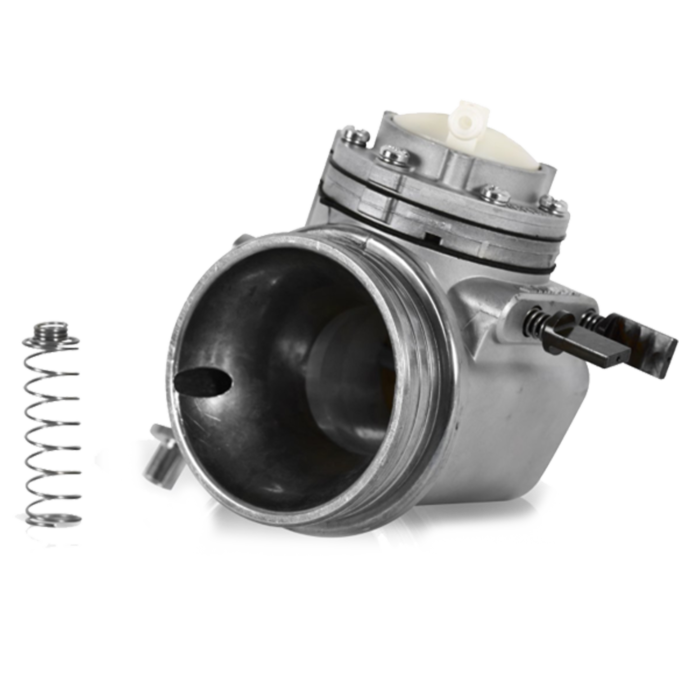

CARBURETTOR

The carburettor is istalled from the front side of the crankcase. The engine is equipped with the Tillotson HW-22B membrane carburetor, 24mm, specifically developed by Tillotson.

The position of the carburettor allows the installation of a standard Karting inlet silencer.

GEAR-DRIVEN BALANCE SHAFT

The gear-driven balance shaft reduces vibrations. It is located in the front of the crankcase. It is composed by the balance shaft itself and the driving gear that also acts as balance element. All the components are made of forged steel, casehardened on the working surfaces.

CRANKCASE AND GEAR COVER

Crankcase and gear cover are built with a specific sand casting process, providing the material with the maximum possible strength and resilience.

The crankcase is designed with extended cooling fins, keeping the temperature securely stable enhancing performance consistency.

EXHAUST

The exhaust is one-piece. Standard or Junior exhaust manifolds are provided according to the engine version.

CRANKSHAFT

The crankshaft is a composed type. Provided with a strong 22mm crankpin and 25mm main bearing journals. The plastic stuffers allow to create the balancing masses without adding undesired volume in the crankcase.

Both the crankshaft and the crankpin are made in forged steel, deeply casehardened on the working surfaces.

TRANSMISSION

The transmission is direct from the crankshaft to the front sprocket and is located on the right side. The chain line is extremely close to the engine’s center reducing crankshaft flexing and bearings solicitations.

The Tillotson Carburettor

The carburettor is placed on the rear side of the cylinder head, with horizontal flow. A specific racing membrane carburettor has been developed by Tillotson, to combine simplicity with the best throttle response and high performance. No fuel pump is required, just a simple connection with the fuel tank.

On demand, a floating chamber carburettor can also be provided by Tillotson, together with the fuel pump. The position of the carburettor allows the installation of a standard karting airbox provided with foam air filter and allowing intake noise reduction.

The IT-250 has been conceived to work 250hrs without any intervention, provided that the oil level is daily checked and the oil itself is replaced once a season. This means that with regular racing activity the TBO is eight years!