REEDSTER V

Tradition & Technology. Constant efforts towards excellence to provide the best racing machines on the planet.

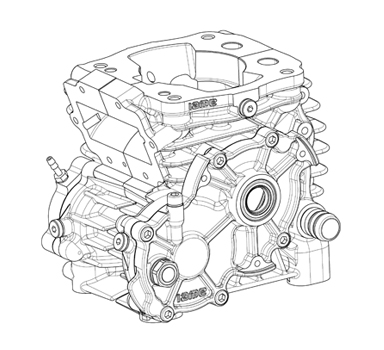

The Reedster 5 is designed to race in top level Karting competitions in the OK and OKJ International categories.

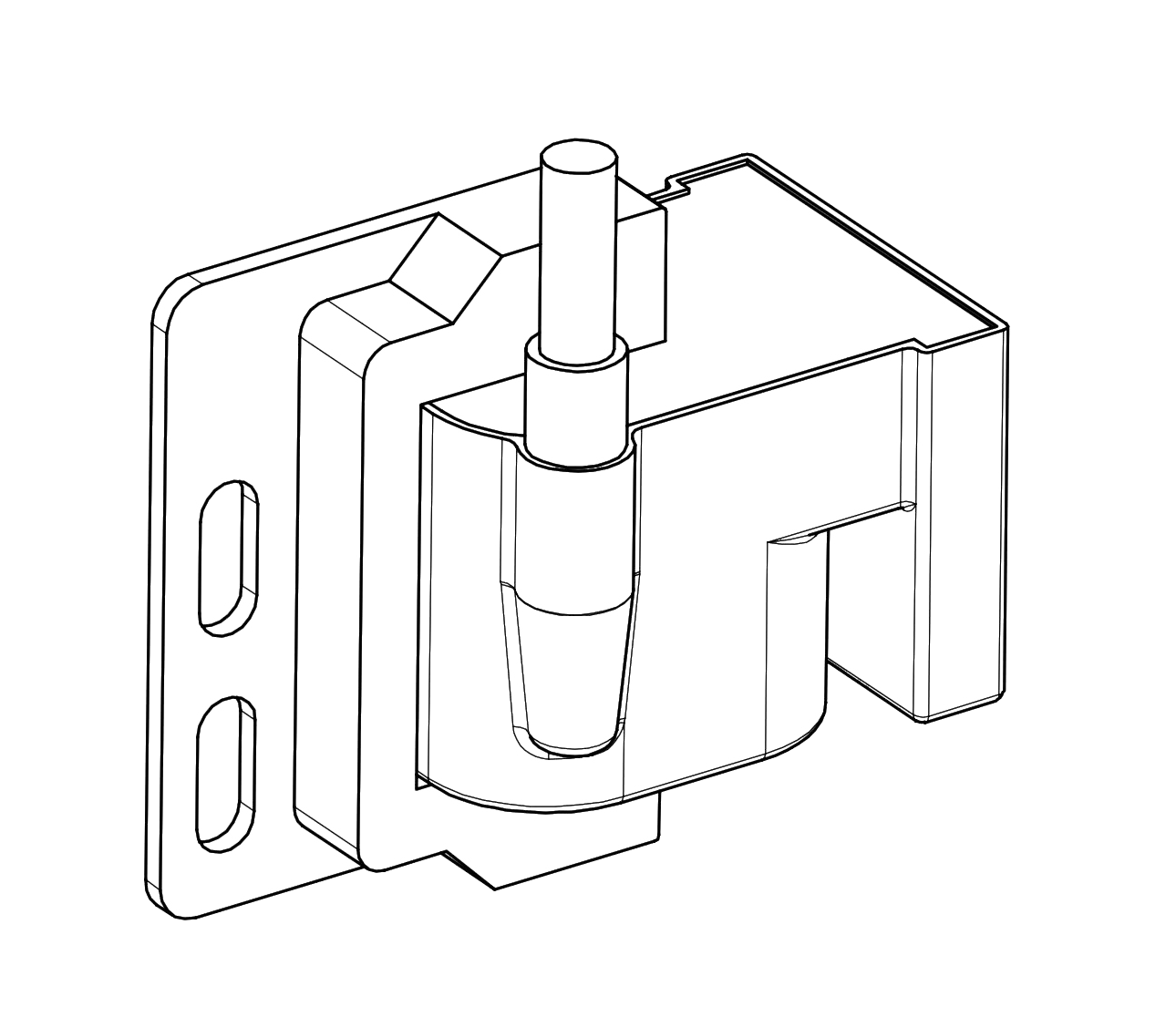

Simplified and efficient Power Valve in compliance with FIA Karting Regulations

Maximum displacement utilization

Essential racing design, compact size, light weight

Limited RPM range compliant with FIA Karting Regulations

Water cooled cylinder, cylinder head and crankcase rear side

Crankcase enhanced air cooling

Direct drive transmission

Integrated balancer shaft with 2 masses symmetrically positioned vs. the cylinder axis

Automatic decompressor on the cylinder head. Easy start. Easier handling of the vehicle off the track

High performance consistency

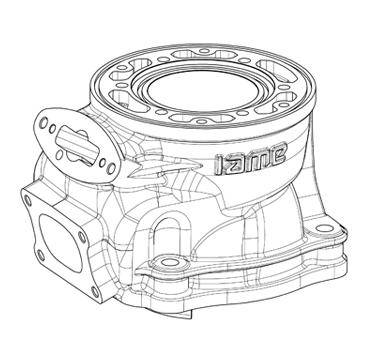

The cylinder is made by sand casting in high-strength aluminum alloy. Completely redesigned on the Reedster V

The new design aims to two specific targets.

Improving cooling circuit efficiency by focusing on the water jacket using CFD software, to optimize the water speed into the jacket and have more homogeneous temperature on the cylinder surfaces.

Lowering material thickness to achieve a more elastic structure.

The cylinder is paired with the cast iron liner manufactured at IAME by precision 5-axis CNC machines. The tight manufacturing tolerances guarantee the consistency of performance throughout the production.

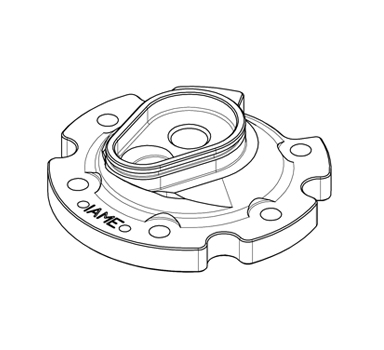

The cylinder head is designed in two separate parts. Made in extruded aluminum alloy by CNC precise machining.

The design of the combustion chamber and cover allows extreme flexibility in shape and and structure.

The automatic decompression valve is installed directly in the cylinder head.

The water jacket in both the cylinder and cylinder head allows an equable cooling on all the surfaces

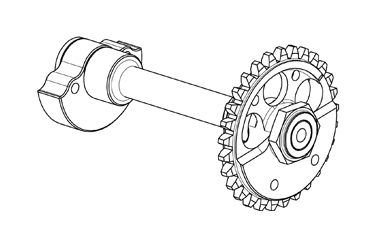

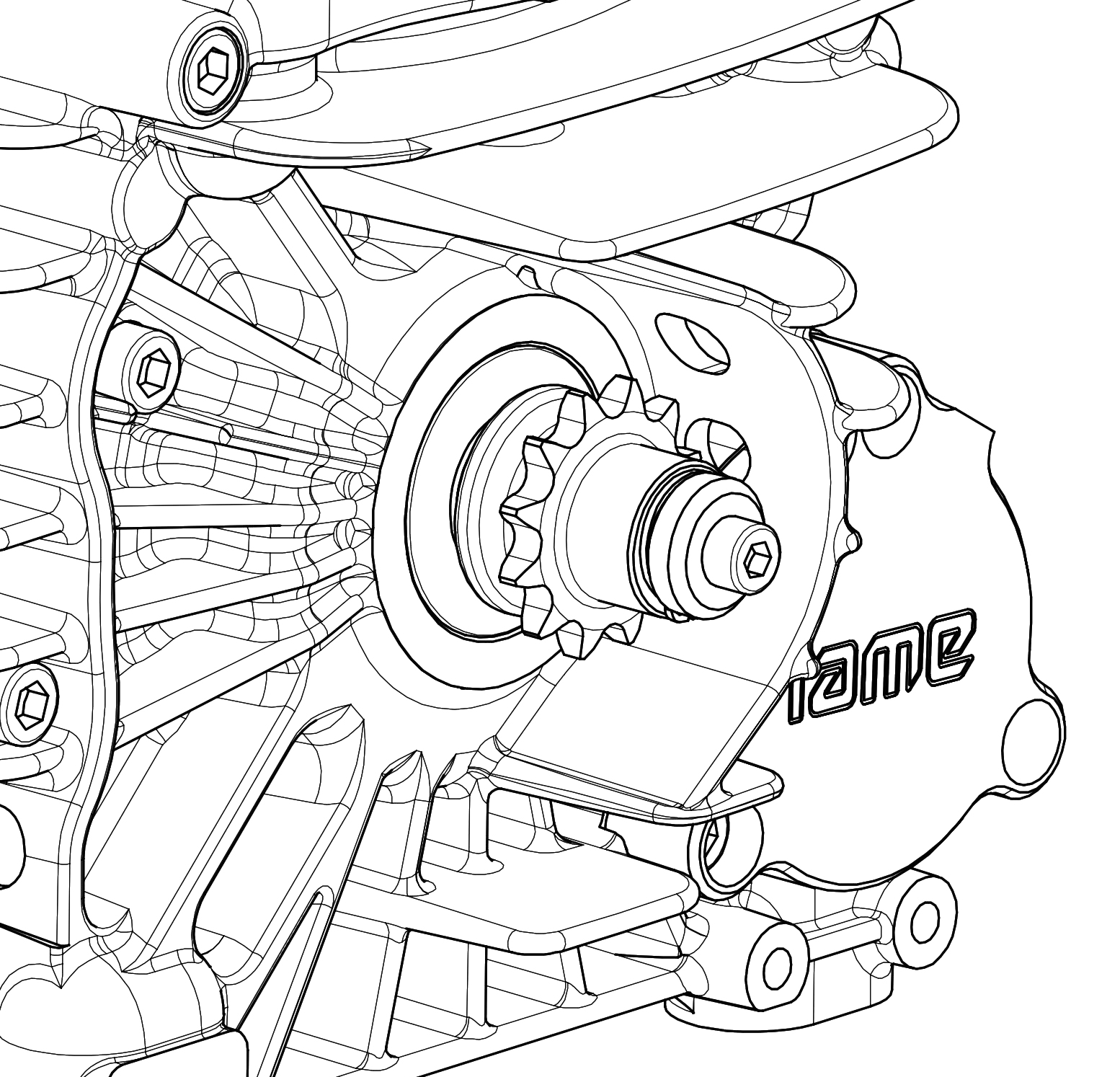

The gear-driven balance shaft reduces vibrations and it’s located in the front side of the crankcase. A state of the art assembly composed of a driving gear incorporating the balance element and a second mass, binded by a specific shaft. All components are manufactured in high strength steel.

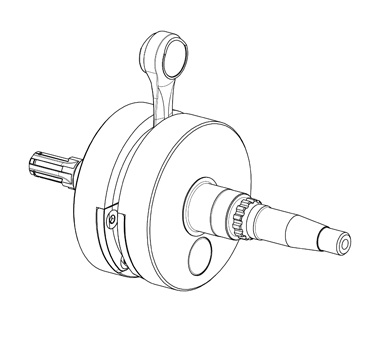

The crankshaft is a composed type. 20mm crankpin and 25mm main roller bearing ensure the best compromise between strength and performance.

The balancing stuffers are made by additive manufacturing.

Both the crankshaft and the crankpin are made of casehardened and grinded forged steel.

The conrod is fully CNC machined from forged steel and provided in a thin “knife shape” design, focused on lightness to guarantee the best performance.

Both conrod ends are supported by precision roller cages.

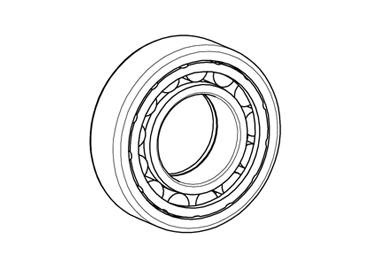

The main bearings are special roller bearings engineered by SKF in cooperation with IAME. The result ensures a significant increase of the crankshaft alignment accurancy and reduces friction.

The inner ring is forced into the crankshaft seats ensuring preservation of the crankshaft journals from wearing and an extremely long life.

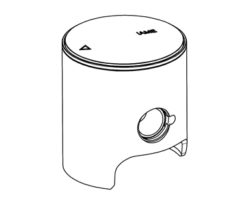

The piston is casted with a particular high-silicon alloy. It is a typical two-stroke design with one chromium plated “L” shape ring.

The Crankcase and Gear Cover are built with a specific sand casting process providing the material with the maximum possible strength and resilience.

The all new air flow design provides maximized cooling efficiency especially between the crankcase and the engine mount.

The transmission is direct from the crankshaft to the front sprocket and is located on the right side. The chain line is extremely close to the engine’s center reducing crankshaft flexing and bearings solicitations.

The ignition is the digital plant made by PVL. The low inertia of the internal rotor reduces solicitations on the crankshaft and helps reducing the engine overall weight.

The locked digital programming sets the rev. limitation .

The electronics are built in the coil, different for OK (16.000rpm) and OKJ (14.000rpm).

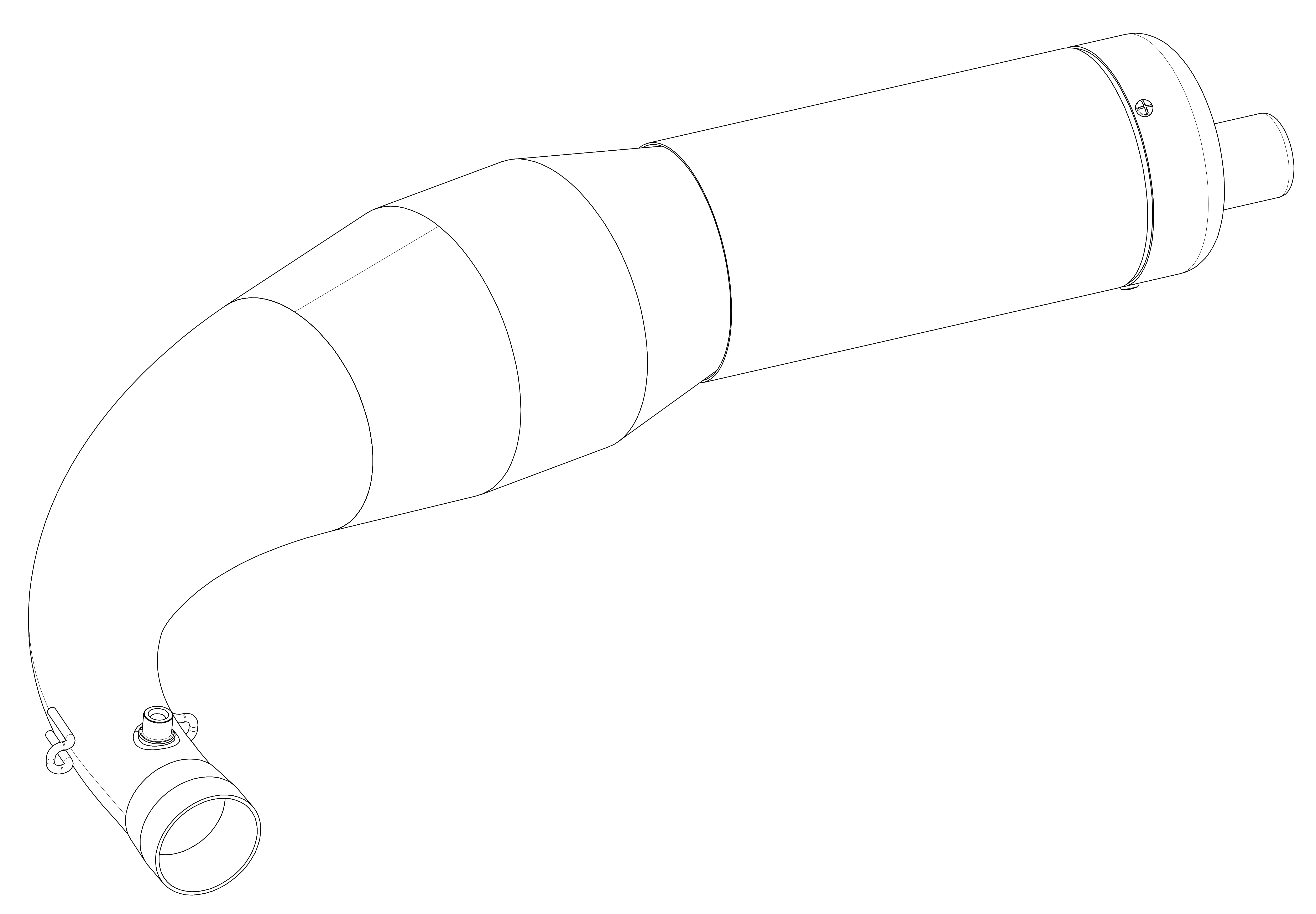

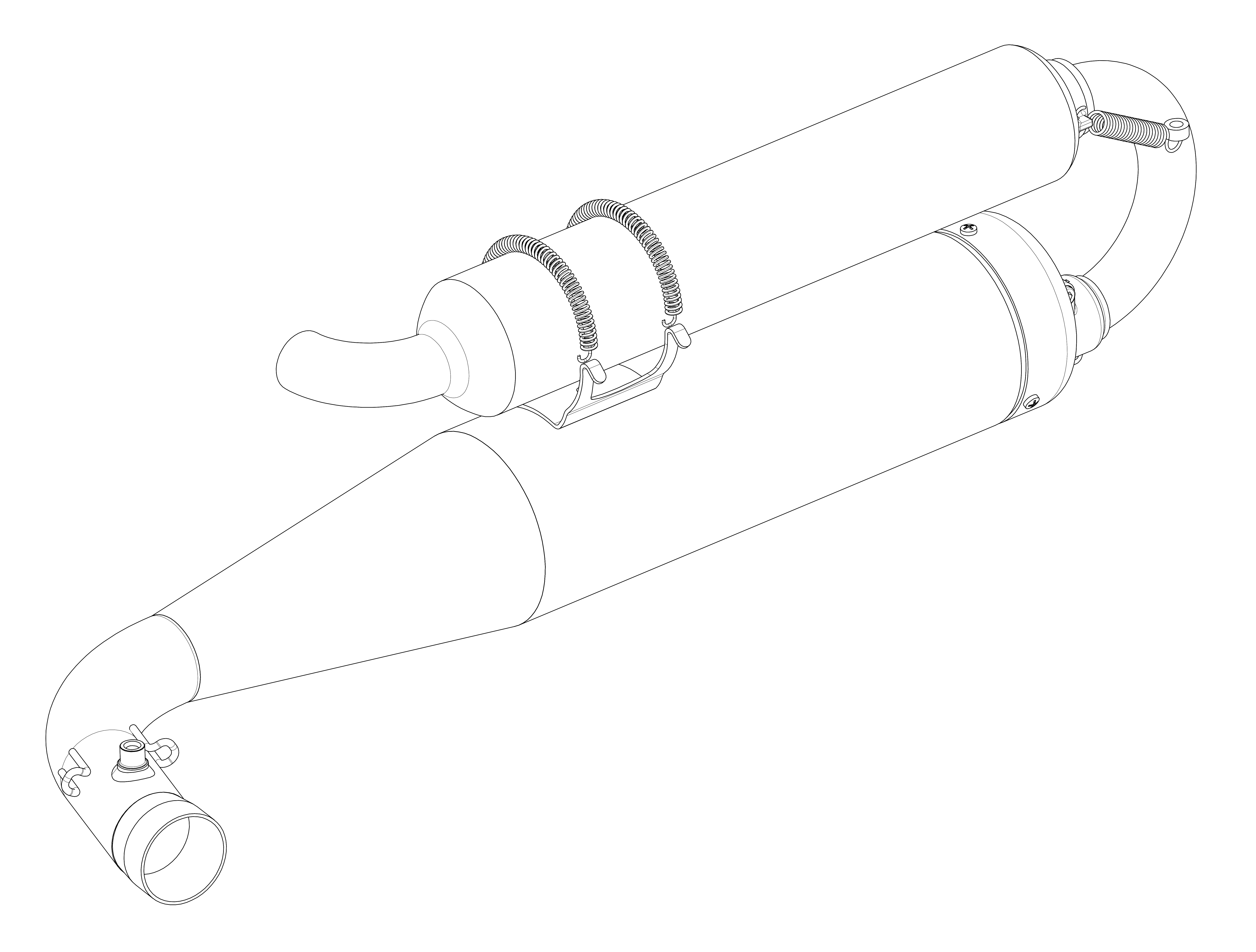

The exhaust is a one-piece design.

Homologated by FIA Karting and specific to OK and OKJ prescriptions.

The OK exhaust

The OKJ exhaust