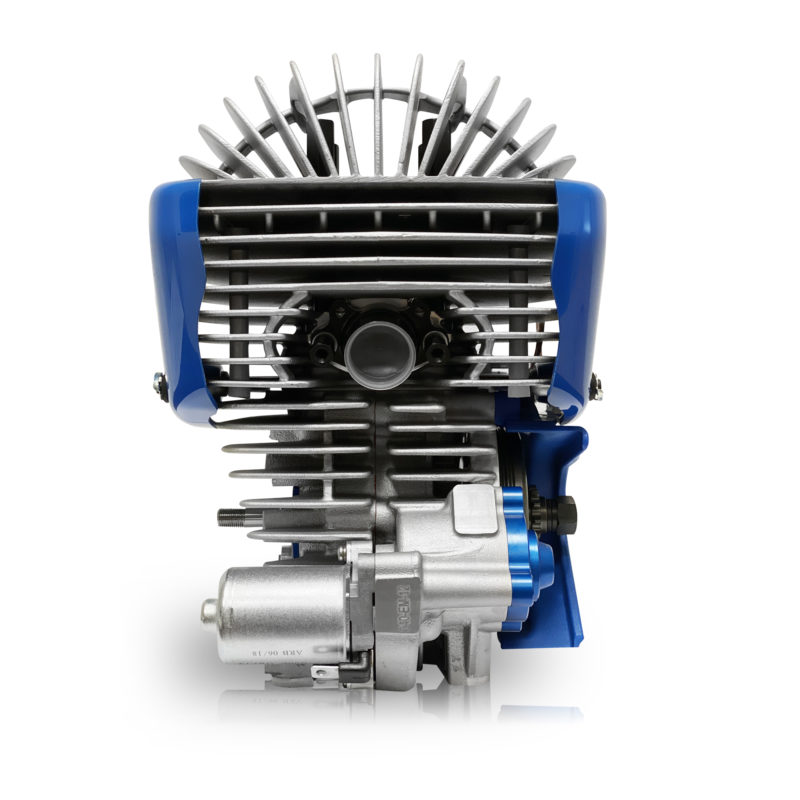

GR-3

Iame GR-3 is is the ultimate 60cc with international CIK-FIA homologation, conceived to compete at the top level for youngsters, in both national and international events.

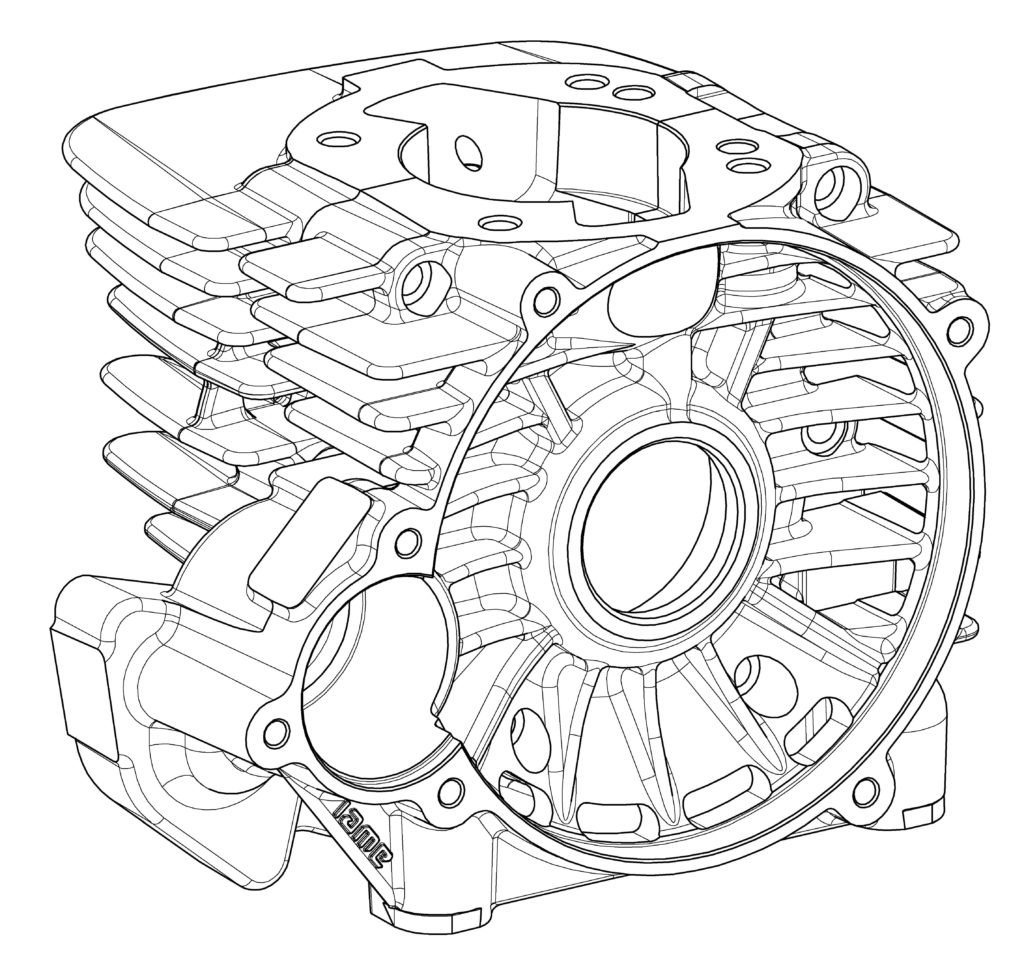

“The right amount of material, in the right place”, like in an aircraft engine

Enhanced cylinder cooling

- by adequate surface and thickness of the fins,

- by studied shape of the lateral flow conveyors

Enhanced crankcase cooling by combination of vertical and horizontal fins able to capture the even turbulent air flow.

Optimized inlet, exhaust and transfers ducts, result of more than one year development

Maximum specific output

Controlled RPM range as per the Regulation

Dry centrifugal clutch (CIK-FIA type)

Chain transmission very close to engine centerline to reduce crankshaft flexion and related friction

Electric starter

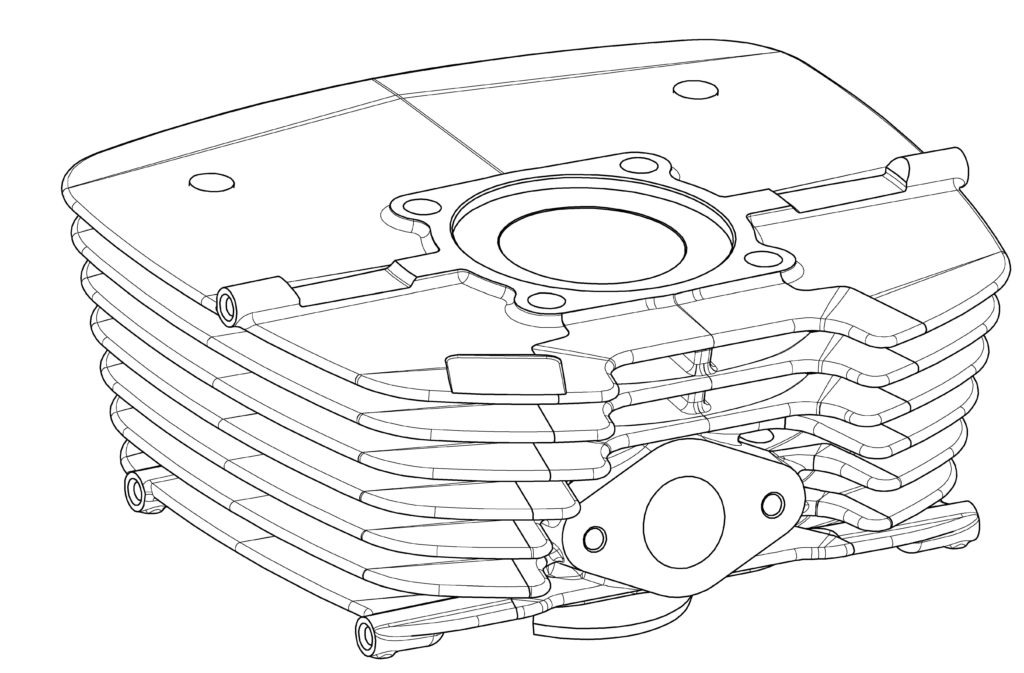

The cylinder, made by gravity casting in high-strength aluminum alloy, it is a completely new design. On an air cooled cylinder the thermal efficiency and the structure stability have the same great importance of the fluid mechanics in the internal ducts. Fins’ shape and extension, combined with fins’ thickness and profile allow the heat to be transferred from the cylinder body to the flowing air.

Air flow conveyors force the air between the fins assuring the maximum possible air flow. “The right amount of material, in the right place” concept makes robust structure without negative heat accumulation. The cylinder is provided with thick cast iron liner, manufactured in IAME by precision 5-axis CNC machines. The tight manufacturing tolerances guarantee the consistency of performance throughout the production.

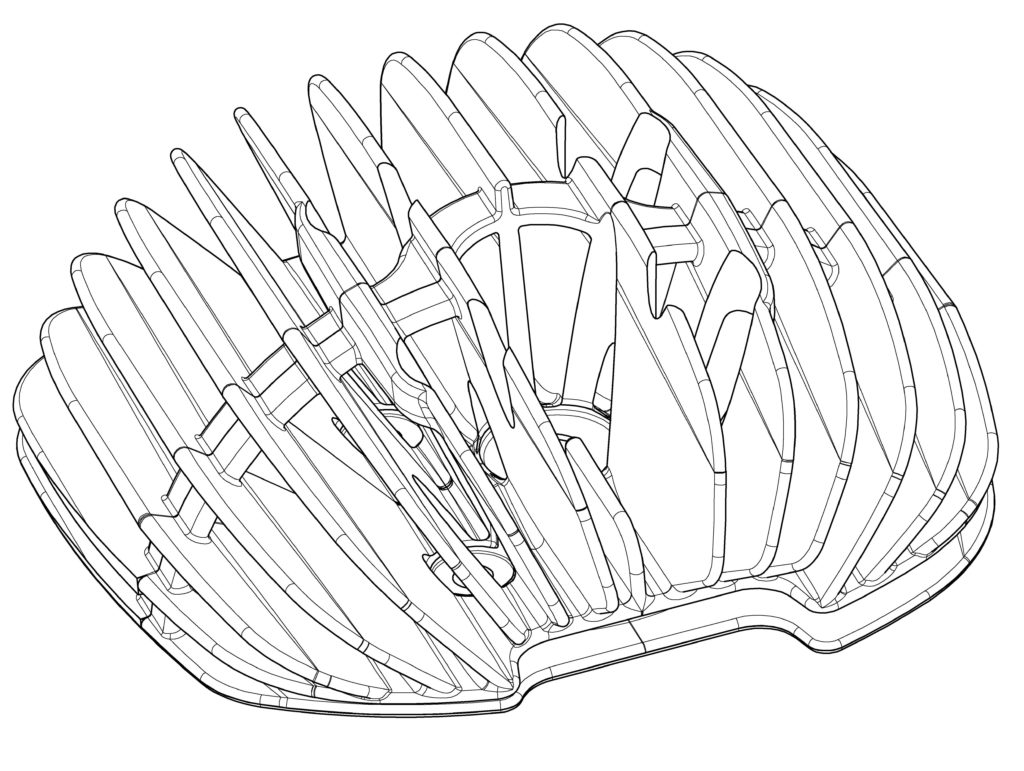

The cylinder head is subject of accurate fins’ design in order to get the correct temperature in the combustion chamber.

In particular the correct air flow is induced between the base fin of the cylinder head and the first fin of the cylinder.

The shape of the central vertical fin allows the use of racing type spark plugs and spark plug caps.

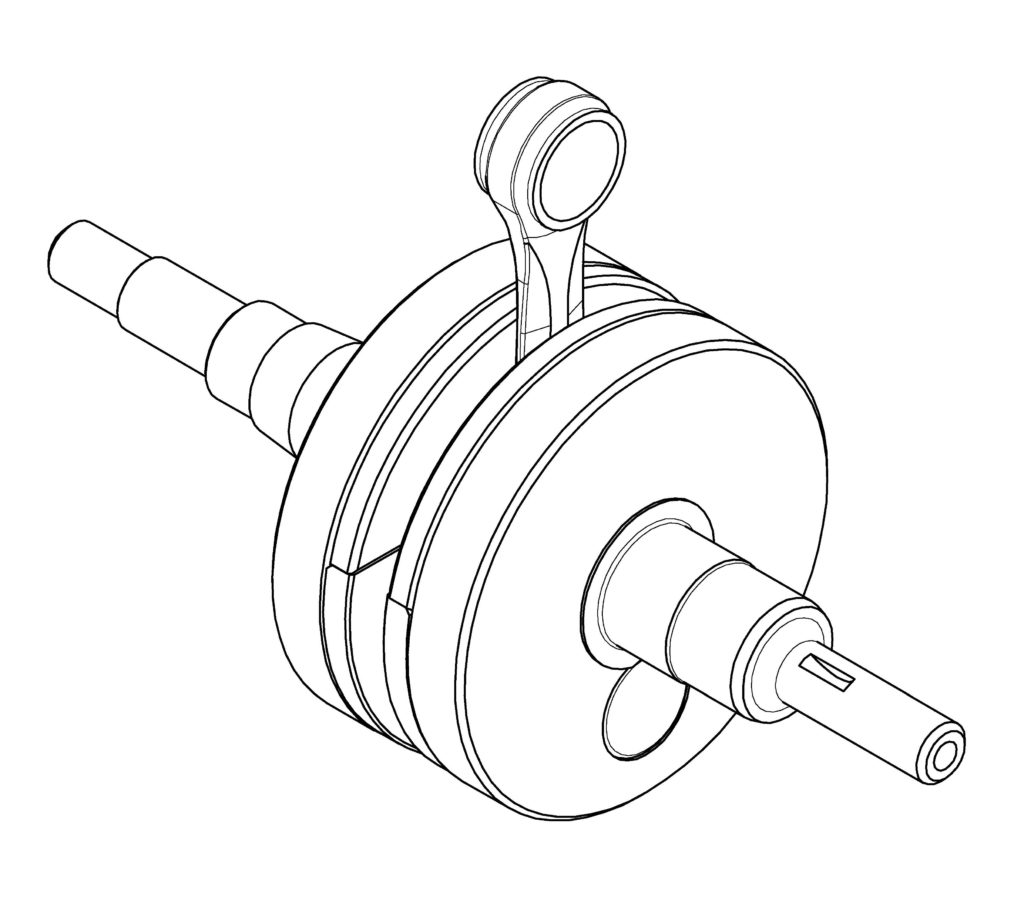

The crankshaft is composed type, with 18mm crankpin and 20mm main bearing journals, On a 60cc engine, the crankshaft must guarantee the best compromise between good stability and reduced friction. The plastic stuffers for balance are made by additive manufacturing.

Both crankshaft and crankpin are made by forged steel, casehardened and grinded.

The conrod, completely CNC machined from forged steel, has very thin “knife style” body. The design is particularly lightened for the best performance, and it’s supported by precision roller cages on both ends.

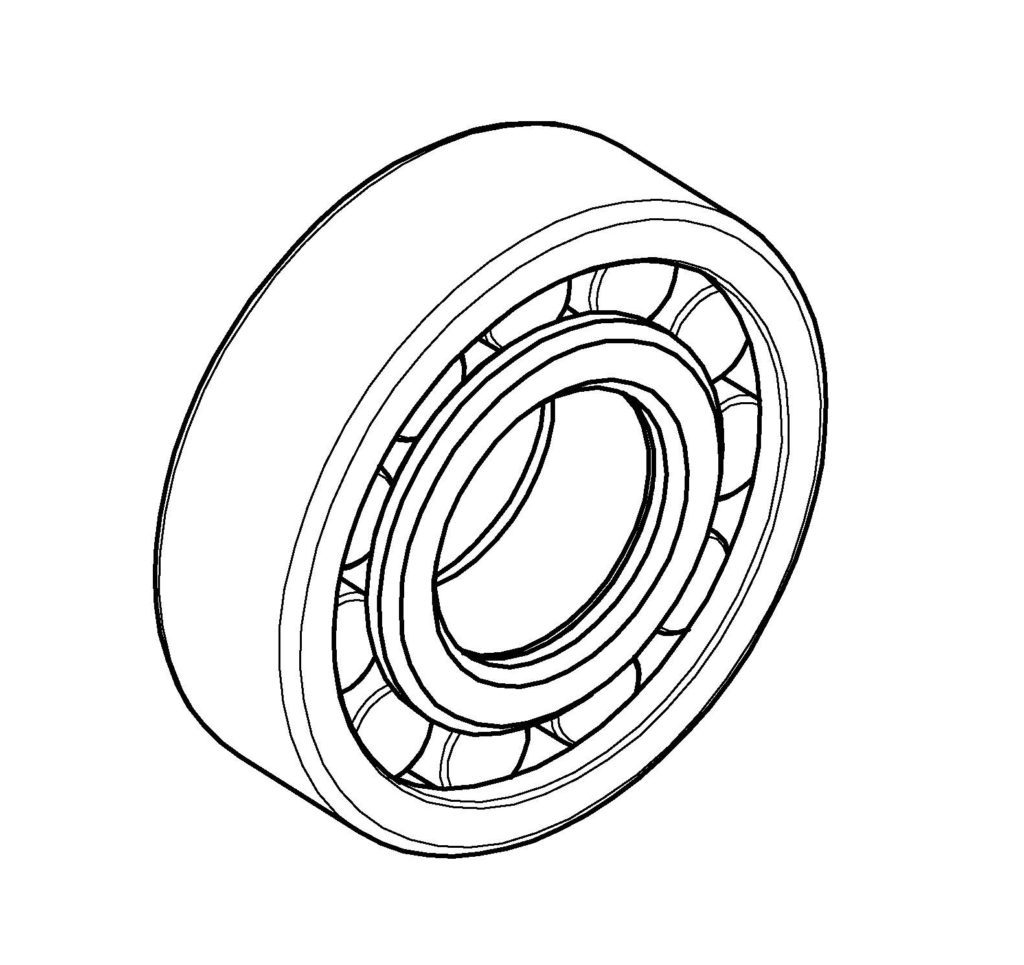

The main bearings are special roller bearings, able to give a significant contribution to crankshaft alignment during engine operation, thus reducing friction.

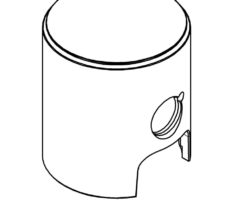

The piston is casted with a particular high-silicon alloy. It is a typical two stroke design with one “L” ring, chromium plated.

The crankcase is built with a particular sand casting process, able to give the material the maximum possible strength and resilience.

Particular attention has been paid to crankcase cooling, keeping into account the turbulent and relatively slow flow able to reach the crankcase.

The transmission is via centrifugal clutch (unique CIK-FIA design) The chain line is extremely close to engine’s center in order to reduce crankshaft flexion and bearings solicitations.

The ignition is digital, with 14.000rpm limiter, CIK-homologated

The exhaust is one-piece, with unique CIK-FIA design.

The electric starter acts on a bi-metallic starter gear, which combines high resistance and long life with low inertia.

The carburettor is Dellorto PHBG18, floating chamber as specified by Regulation.