SCREAMER 3

Tradition & Technology. Constant efforts towards excellence to provide the best racing machines on the planet.

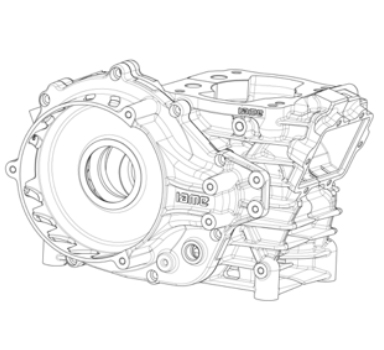

The Screamer III is the brand new engine model launched in 2019 to compete in the challenging KZ/KZ2 gearbox classes.

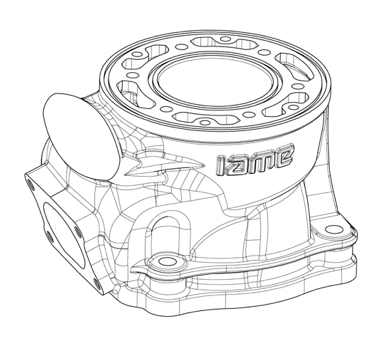

New design cylinder, vertical axis

Maximum displacement utilization

New design crankcase, compact dimensions, light weight, robust structure

Efficient air cooling of the crankcase front and bottom

Water cooling for cylinder, cylinder head and back part of the crankcase

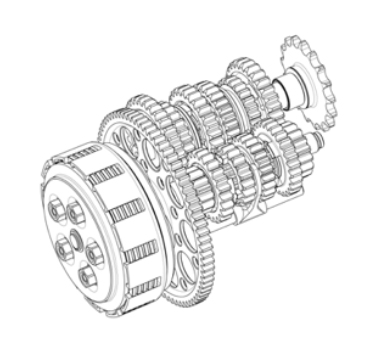

Precision, low friction gears

Dry clutch

High performance consistency

The cylinder, made by sand casting in high-strength aluminum alloy, has been completely redesigned.Two targets have been pursuit.

– To improve the cooling efficiency by focusing on the water jacket using CFD software, in order to optimize water speed into the jacket and have more homogeneous temperature on the cylinder surfaces.

– To reduce material thickness in order to have a more elastic structure and less thermal accumulation.

The cylinder bore is Ni-Si coated.

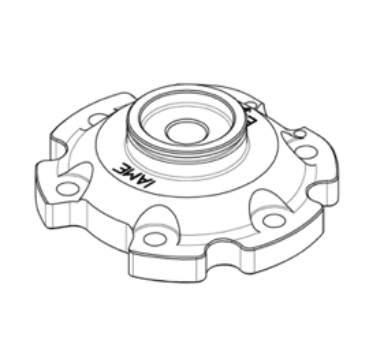

The cylinder head is in two parts, made in extruded aluminum alloy by CNC precise machining. The design of both combustion chamber and cover allow extreme flexibility about shape and structure.

The cylinder head in two parts allow easy squish and cylinder position adjustment without limits.

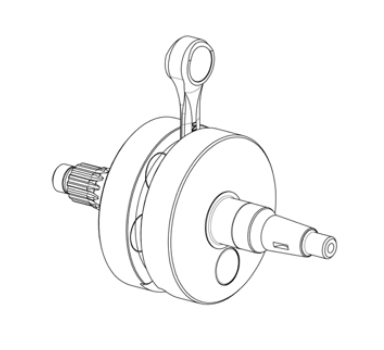

The crankshaft is composed type, with 20mm crankpin and 25mm main bearing journals, the best compromise between strength and performance. The balance is achieved by metallic inserts, allowing the typical disc-shape crankchaft.

Both crankshaft and crankpin are made by forged steel, casehardened and grinded.

The conrod, completely CNC machined from forged steel, has the “knife style” body. The design is particularly robust to contain deformation and extend conrod’s lifetime. It’s supported by precision roller cages on both ends.

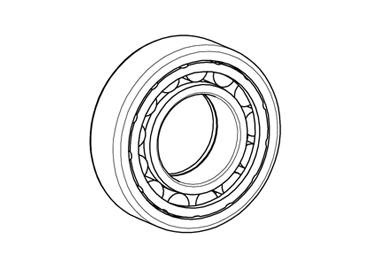

The main bearings are special roller bearings created by SKF in cooperation with IAME, able to help significantly the crankshaft alignment during engine operation and reduce friction.

Having the inner ring forced onto the crankshaft journals, they protect the crankshaft from wearing and have an extremely long life.

The piston is casted with a particular high-silicon alloy. It is a typical two stroke design with one flat steel ring, chromium plated.

Crankcase and primary transmission cover are built with a particular sand casting process, able to give the material the maximum possible strength and resilience.

The crankcase is designed to take benefice from the air flow, with efficient cooling especially between crankcase and engine mount.

The new position of the “desmo” cam and preselector mechanism allow the best location of the gear shifting lever.

The resulting short and straight shifting rod between chassis and engine makes gears shifting even more precise and rapid, and avoids any eventual interference with the seat supports.

The new design has really compact dimensions and allows a significant weight reduction.

The water cooling jacket is present between gearbox compartment and crankshaft housing, to grant an efficient thermal separation.

The transmission is 6-gears gearbox with 5-discs dry clutch to minimize the power loss.

The lubrication of the primary shaft (standing above the oil level) is assured by a dedicated circuit.

The free gears are supported by needle bearings so to reduce friction, and the chain line is extremely close to engine’s center in order to reduce secondary shaft flexing and bearings solicitations.

The ignition is analogical, homologated by CIK-FIA.

The exhaust is typical 13-sectors, homologated by the CIK-FIA is the same for the two categories.